Need of Motor Starting Solution

- Induction Motor during starting generates high starting current (Typically 6 to 7 times of full load current)

- These leads to sudden dips in voltage & sudden jerk on the equipment

- Such high current may results in increase winding temp, weakening winding & other adverse effect.

- Hence it is preferred to start motor with FCMA/ Electronic soft starter or variable frequency drive (VFD).

Benefits of Motor Starting solutions

- The Lower inrush current of Soft Starting reduces mechanical stress and minimizes penalties from the utility company.

- Extending system lifetime due to reduced mechanical wear on:

- The Motor

- Belts and pulleys

- Gears and chains

- Couplings and bearings

- Cavitation and water hammer in pumps

Reducing electrical effects:

- Reducing the heavy current surge on the electrical supply which can be severe enough to cause voltage dips and flickering lights.

- Pitting and burning of contacts due to high currents which are many times the motor full-load current.

- The power cables run cooler.

- Less stress upon Electrical Distribution system.

A) FCMA Soft Starter

BENEFITS OF FCMA SOFT STARTER

- Easy to Install & Operate.

- Harmonic free starting eliminates electrical supply disturbance.

- No Electronic component hence highly reliable in harsh electrical supply conditions like low voltage& frequency.

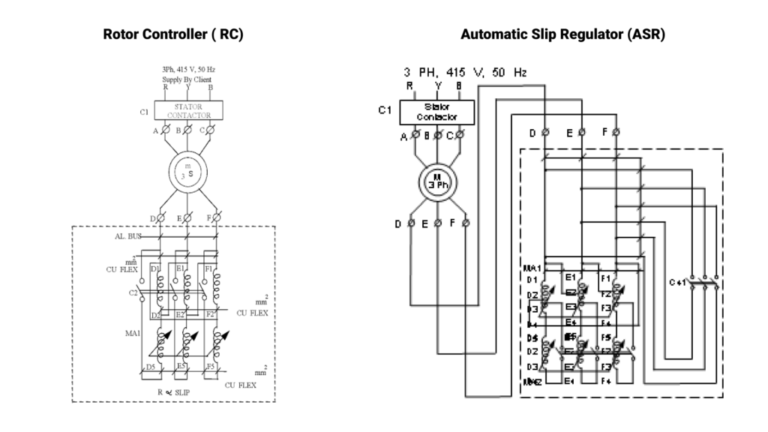

- FCMA soft starter can be used for Squirrel cage as well as slip ring motors.

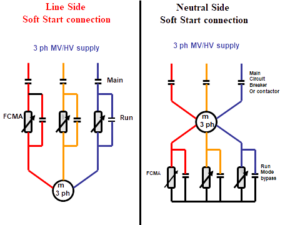

- Available in Line side & Neutral side models.

- Almost fail safe

- Suitable for hazardous conditions like chemical, steel, sugar etc.

TYPES OF FCMA SOFT STARTER PRODUCTS

TYPES OF FCMA SOFT STARTER PRODUCTS

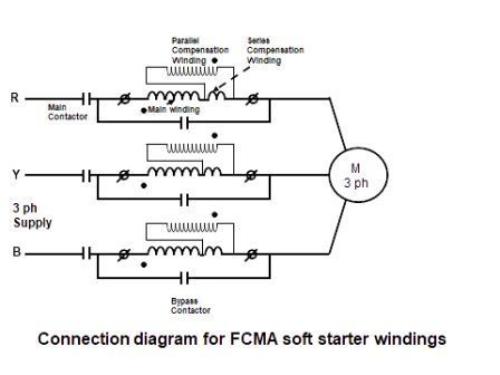

- Soft Starter for a squirrel cage motor: Flux compensated Magnetic Amplifier (FCMA) soft starters are step-less reduce voltage starters that ensure a constant low starting current with incremental voltage and torque to the motor to achieve smooth acceleration of the motor.

- Application of Squirrel Cage Motor: Pump, Fan, Blower, Compressor, Chiller, Test Bed etc.

- Models Available: FCMA Soft Starter wiring diagram.

- Application of Slip Ring Motors: Leveler, Cutter, Fibrizor, Cane Chopper, Ball Mill, ID Fan, Mixing Mill, Shredder, etc.

- Models Available:

We offer following rating of FCMA soft starter :

- LT soft starter : – 11KW to 3MW for voltage 220 to 690 volts.

- MV/HT soft starter : – 100KW to 10MW for voltage 2.2KV to 11KV.

B) Electronic Soft starter & Variable Frequency Drive (VFD)

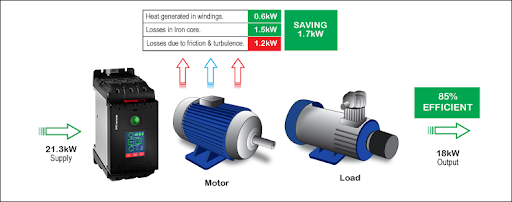

When any AC induction motor becomes lightly loaded, the power factor and the efficiency decrease. This is caused by the inherent design of the motor and the laws of physics, and leads to energy being wasted. These are known as excitation losses.

Soft Starter continually monitors the power factor, recognizing when the motor is becoming lightly loaded and then instantly employing strategies to reduce the losses by controlling the voltage and current supplied to the motor to match the load conditions. This not only increases the part load power factor, but reduces the energy consumption in kW.

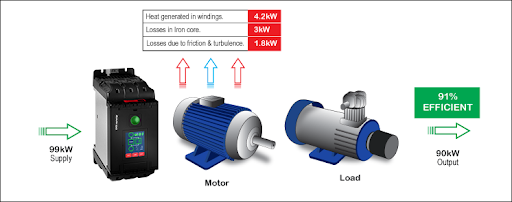

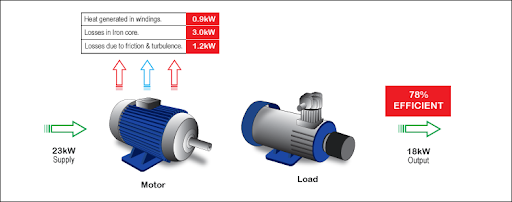

When the motor becomes fully loaded, the power factor increases, and Soft starter automatically bypasses itself to ensure the most efficient use of energy in all motor load conditions.See this example of the energy savings that could be made using Our Electronic Soft starter.

90kW Motor Running at 100% Load

90kW Motor Running at 20% Load

90kW Motor Running at 20% Load with energy saving Electronics Soft Starter